Achieving great results with the Mitre Sled starts with well dimensioned timber boards and in particular, timber boards with parallel edges. In this post, we discuss a method of getting parallel sided boards, dimensioned to the width you want by using your router table and a simple fence and featherboard setup. This method assumes that you can start with boards with at least one straight side of the board that may have been straightened by passing it over a jointer or similar.

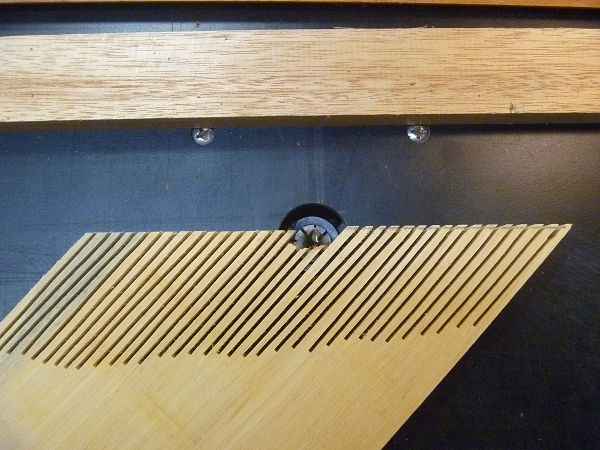

The featherboard used in this method is made by cutting a wide board at approximately 45 degrees and then running a number of slots in the featherboard face using a bandsaw or similar. Next, the ends of 2 or 3 tines in the middle of the featherboard are removed to accommodate your cutter. Finally, the last 1-2mm of the end of all the tines leading into the cutter are removed. This is because the board width prior to cutting will be 1-2mm wider than after the board has passed the cutter, so to ensure the featherboard applies even pressure to the board both before and after it has passed the cutting blade, the featherboard tines need to be slightly different lengths before and after the cutter notch.

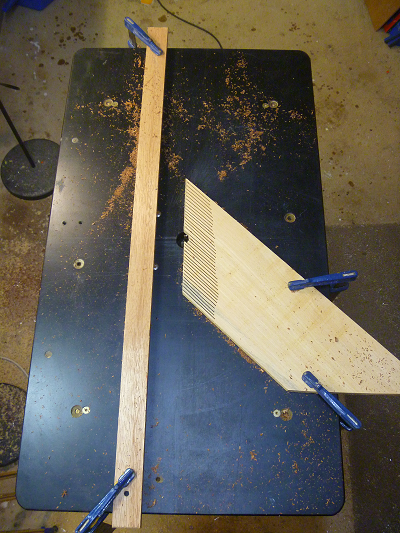

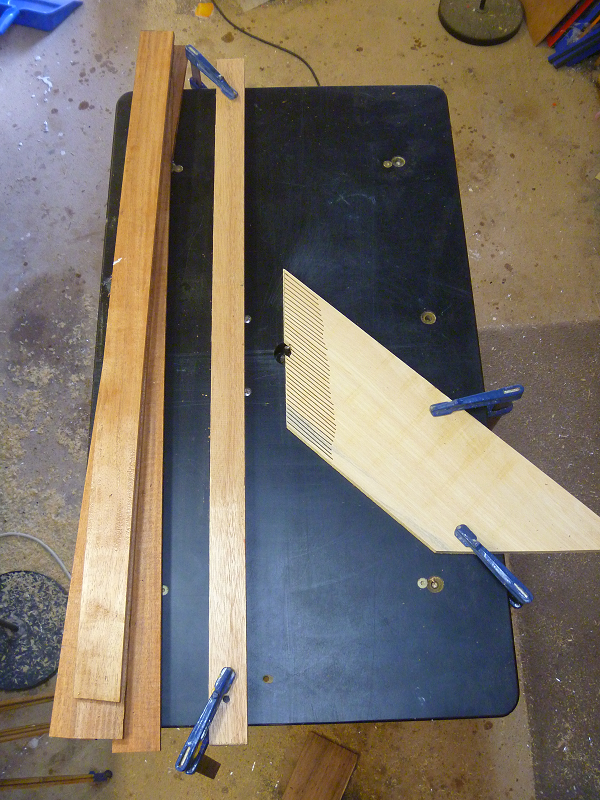

Clamp the featherboard to the router table so that it surrounds the cutter and use at least 2 clamps to prevent it from twisting away when you push a workpiece past it. Then, simply clamp a straight long timber fence to the router table approximately parallel to the featherboard tines. This fence can be clamped almost any distance away from the cutter to obtain the desired board width.

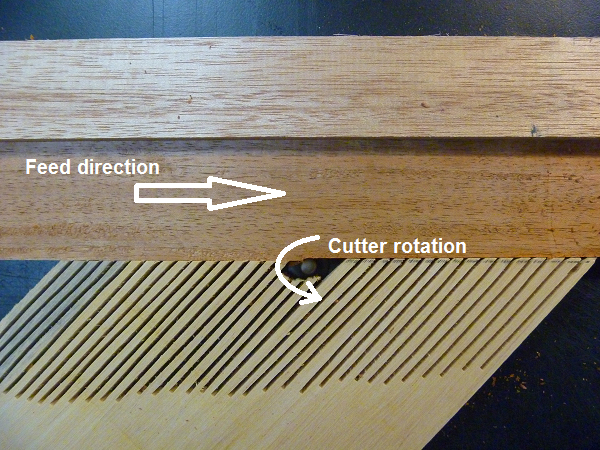

When feeding timber boards through this setup, only take 1-2mm off at each pass and consider using a spiral cutter for a very smooth surface edge finish. The image below shows the feed direction of the timber boards and cutter rotation. Normally, you would not pass boards past a cutter this way as the cutter rotation tries to pull the board off the fence. The featherboard stops this from happening and helps prevent tearout

Timber boards with parallel sides are essential for getting good results with the Mitre Sled. This is because the cutting process with this jig requires each side of the board to be registered against the jig fence to cut the mitres on each end of the board. If the two edges of the board are not parallel, the mitres may not align accurately.